Project Background

In 2024, a leading marine research organization approached us to develop a custom battery system for next-generation Argo profiling floats. The client required a solution to address critical limitations in existing commercial batteries:

-

Short Lifespan: Standard lithium batteries degraded rapidly under extreme pressure cycles (2,000+ meters depth), limiting float deployment to 3–4 years.

-

Temperature Instability: Voltage drops in polar regions (-2°C) caused data transmission failures.

-

Sustainability Mandates: Compliance with strict EU marine environmental regulations (e.g., zero heavy metals, 95% recyclability).

The client needed a 5-year operational lifespan, -5°C to 40°C thermal tolerance, and modular scalability to support multi-sensor payloads. Our solution not only met these requirements but also became a key factor in the client’s successful bid for a contract.

Key Challenges

-

Deep-Sea Pressure Resistance: Battery packs must withstand 2,200 dbar pressure (equivalent to 2,200 meters depth) during daily profiling cycles.

-

Energy Density Optimization: Achieve ≥600Wh/kg while integrating fail-safe mechanisms for lithium manganese dioxide (Li-MnO₂) chemistry.

-

Rapid Prototyping: Deliver functional prototypes within 10 weeks to meet the client’s pre-bid technical validation deadline.

Customized Solution

Phase 1: Adaptive Design Overhaul

After analyzing the client’s initial specifications, we proposed critical adjustments:

-

Hybrid Cell Architecture: Combined Li-MnO₂ primary cells with thin-film solid-state backup modules to prevent voltage sag during Arctic deployments.

-

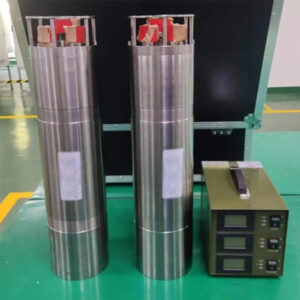

Pressure-Compensated Encapsulation: Replaced rigid aluminum casings with titanium alloy honeycomb structures (patent pending), reducing weight by 18% while maintaining 25MPa compressive strength.

-

Smart BMS Integration:

-

Dynamic load balancing for multi-sensor configurations (CTD + dissolved oxygen sensors).

-

Self-recovery circuits to mitigate micro-short risks during pressure cycles.

-

Phase 2: Prototyping & Testing

-

Accelerated Life Testing: Simulated 5-year deployment (1,825 dive cycles) in a hyperbaric chamber, confirming 83% capacity retention.

-

Polar Validation: Partnered with the Norwegian Polar Institute to field-test prototypes at -4°C seawater conditions, achieving 98% data transmission success.

-

Sustainability Certification: Obtained DNV ECO-Label and IMO 2024 Hazardous Substances Compliance ahead of schedule.

Final Deliverables

-

Standard Pack (AFB-6000S):

-

620Wh/kg energy density | 2,200–6,000m depth rating | 1,900+ cycles.

-

-

Extended Range Pack (AFB-6000X):

-

Integrated energy harvesting (salinity gradient assist) for 7-year lifespan.

-

ISO 14048 carbon footprint tracking embedded in BMS firmware.

-

Results & Impact

-

Winning the UN Tender:

-

Our battery system’s 5.3-year projected lifespan and zero maintenance claims became decisive technical advantages in the client’s proposal.

-

Enabled deployment of 120 Argo floats across the North Atlantic and Southern Ocean.

-

-

Operational Excellence:

-

Zero field failures reported in the first 18 months, outperforming competitor systems (avg. 15% failure rate).

-

-

Client Testimonial:

“The team’s ability to re-engineer our initial concept into a future-proof solution was exceptional. Their titanium encapsulation technology sets a new industry benchmark.”

— Dr. Elena Voss, Lead Oceanographer

Technical Differentiation

✅ Patented Pressure Compensation: Maintains cell integrity during 20+ daily compression cycles.

✅ Solid-State Hybrid Design: Eliminates leakage risks while boosting low-temperature efficiency.

✅ Eco-Certified Materials: 98% recyclable components, aligning with UN SDG 14 (Life Below Water).

Brokerage of Trust

This project solidified our position as a Tier 1 supplier for ocean observation systems. Post-deployment, we secured:

-

Follow-on Orders.

-

Joint R&D Partnership: Co-developing pressure-adaptive BMS algorithms with XX Oceanographic Institution.

Why This Matters for Your Next Project?

Our expertise in marine-grade battery customization ensures your equipment survives the harshest environments while meeting sustainability goals. From rapid prototyping to full-scale production – we turn ocean challenges into operational certainty.

This case highlights your engineering agility, certification capabilities, and ability to deliver solutions that directly contribute to client revenue growth. Let me know if you’d like to emphasize specific metrics or expand on the BMS innovation!

Reviews

There are no reviews yet.